OUR PROCESS

3142

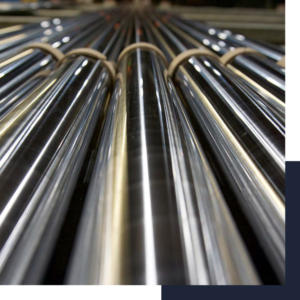

INDUCTION HARDENING

Induction case hardening is one of IHC’s areas of special expertise. Two induction hardeners change a bar’s surface properties and make it more impact-resistant while the IHCMS stores customer specifications, detailing case hardness and depth. Our consistent feed rates and controlled quench practice produce a homogeneous product with predictable machining characteristics. There are no surprises, bar to bar and order to order.

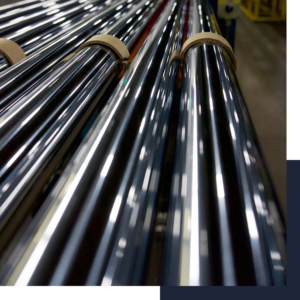

STEEL POLISHING

The surface substrate is critical in achieving proper chrome adhesion and is directly correlated with corrosion resistance performance. This is the last step before entering into a chrome plating bath.

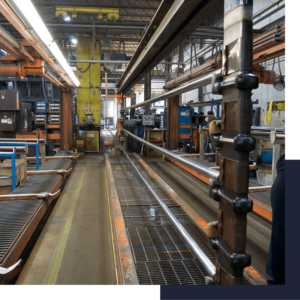

CHROME PLATING

To guarantee the best result, we use a proprietary plating solution and system wide IHCMS control. Nothing is left to chance. IHCMS precisely times, prioritizes, sequences and schedules your order. We continuously monitor the temperature, heat, cooling solution level, plating bath makeup and concentration, and we only use reverse osmosis treated water in the tanks to eliminate water-borne impurities.

Because plating decreases chromium in the tanks, the IHCMS injects chromium after each plating cycle. Incorporated into the IHCMS is a 24/7, ion exchange chromium renovation system that continuously removes metals so the plating bath is virtually new for every plating job. Our filtration system moves from tank to tank removing micron-sized particles and filters each tank several times. We use a superior ventilation system that exceeds all EPA and OSHA standards. This combination is the world’s best chrome plating system and produces consistent perfection, bar to bar and order to order.

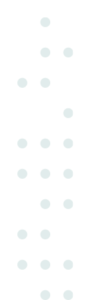

CHROME POLISHING

After plating, bars or tubing are processed again through multi-station polishers and buffers designed and built to our specifications… As in the other processes, the IHCMS controls the process, so your order data is retained for instant re-call.

At each polishing belt and buffing station the bar’s finish is enhanced; and because the whole process is precisely controlled, the finished product is as perfect as a chromed bar or tube can be. They’re so perfect, and so beautiful… our chromed bars & tubes are often called, “Industrial Jewelry”.